YEN NGOC BIRD’S NEST strives to transcend the confines of traditional family business, relentlessly crafting a premium EBN brand where heritage converges with modernity. We not only focus on diversifying EBN products but also aim to produce export-standard nests, meticulously cleaned to meet the health assurance needs of consumers.

To achieve this, the production and cleaning processes are tightly controlled from start to finish, encompassing the following steps:

❶ Selection and harvesting of nests

Edible bird’s nests are meticulously selected and manually harvested from controlled environments, free from contact with biological pollutants or heavy metals. Only nests that meet the standards and are left behind by the swiftlets after their breeding season are harvested to ensure no harm to the birds or their offspring.

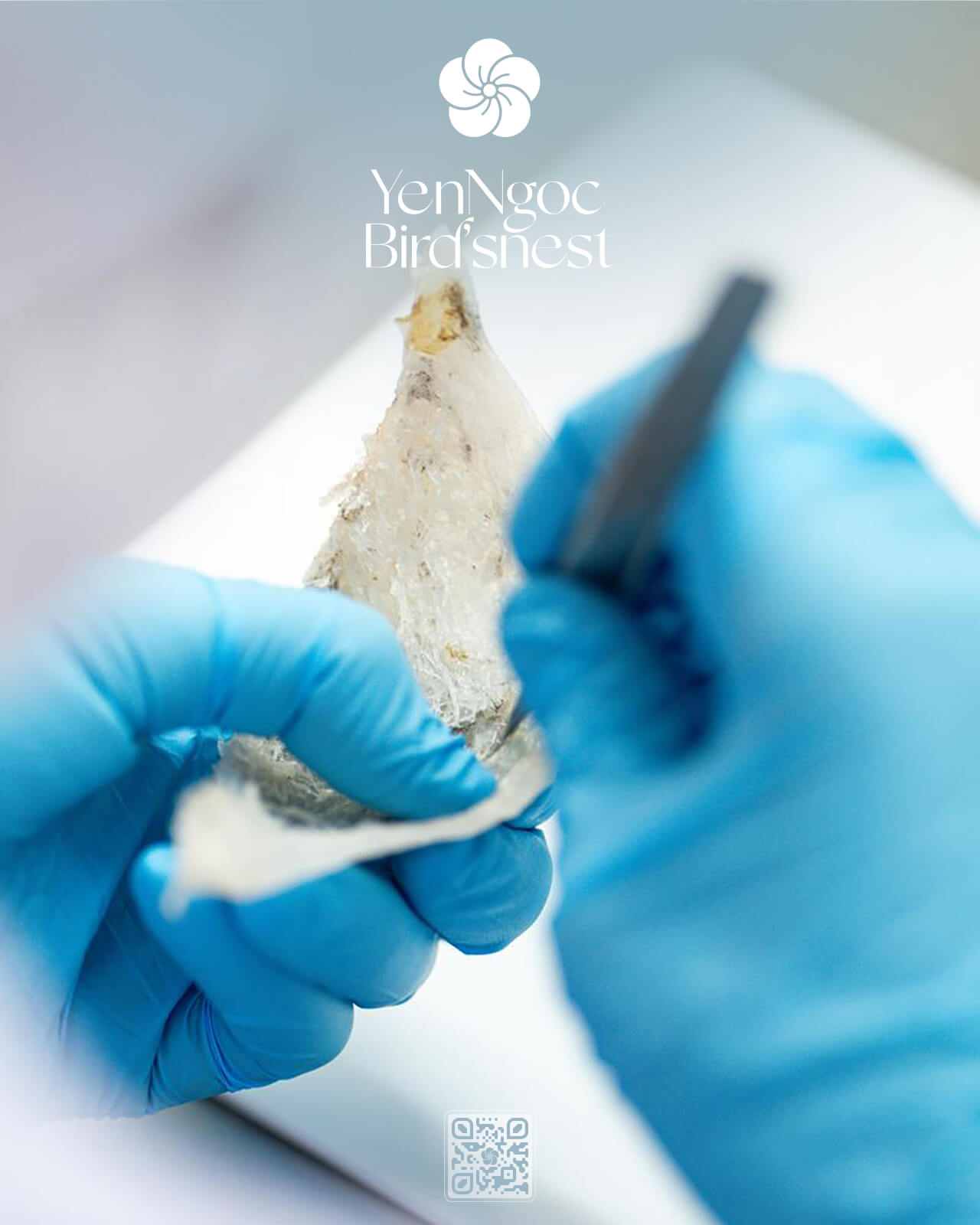

❷ Hand-cleaning of nests

The cleaning process requires a significant amount of time and skilled manual labor. The edible bird’s nests are washed and soaked in water that has passed through a filtration system to facilitate the separation of impurities. YEN NGOC BIRD’S NEST refrains from using any additives, preservatives, or industrial bleaching agents, despite their recognized safety and permissible dosage. YEN NGOC BIRD’S NEST aims to ensure its products are the most natural and 100% pure swiftlet’s nests.

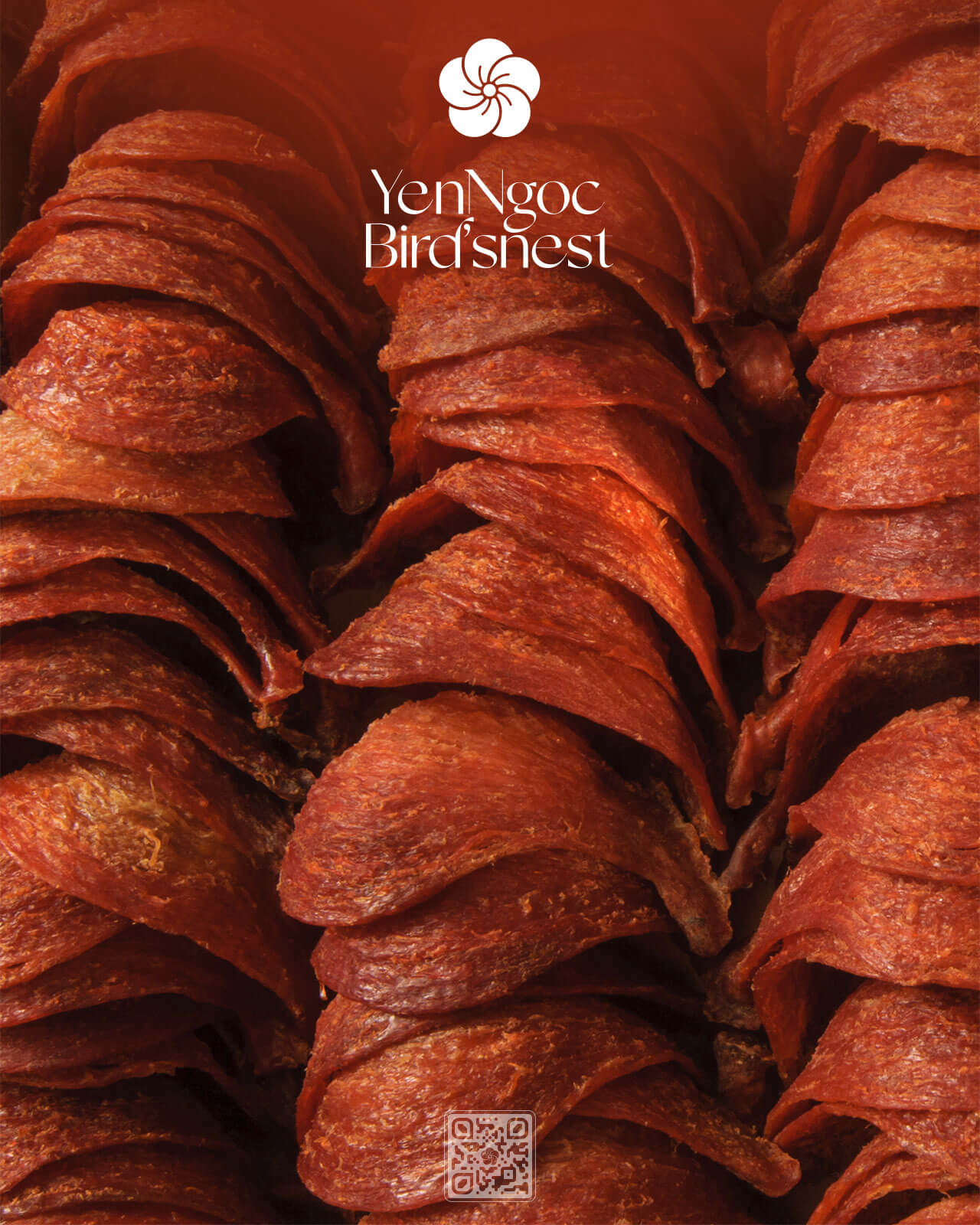

❸ Molding and shaping

After the cleaning process, fresh edible bird’s nests are arranged in molds shaping them into visually appealing blocks following specific standards, with quantities (strands/blocks) and weights that create the distinctive, attractive blocks of YEN NGOC BIRD’S NEST.

❹ Drying and sterilization

The final step involves drying and sterilizing using specialized drying machines before sealing with PE food-grade packaging, completing the packaging of the finished product delivered to our valued customers.